Final Processing

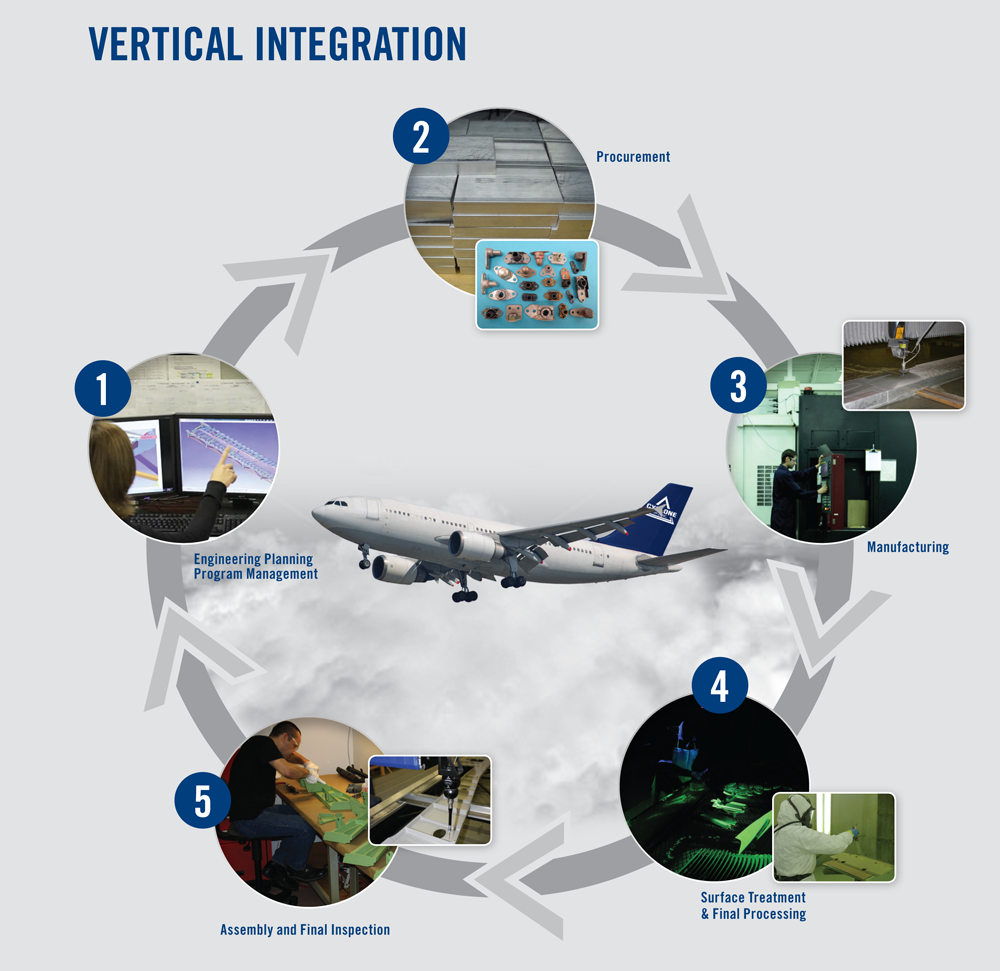

Automated state of the art facilities for multiple surface treatment processes reduce cost and allow for shorter lead times by removing the need to outsource. By combining all processing under one roof, Cyclone helps clients eliminate needless shipping and minimize logistical planning. Cyclone’s vertical integration guarantees cost-effective, comprehensive and reliable service.

Cyclone’s surface treatment and enhancement workshop is AS14001 compliant. Unsurpassed environmental controls and waste management means no discharges into the environment.

Cyclone’s processing facility is able to perform the following:

Heat Treatment

Cyclone’s Heat Treating is approved to NADCAP specifications and features drop-bottom and artificial aging furnaces designed to heat-treat and age both rough and machined aluminum parts. Automated to maximize efficiency, these machines ensure quality without long lead times.

Drop Bottom Furnace for Aluminum Parts

- Designed and built to NADCAP specifications

- 6 Second Quench Delay

- 48″ x 48″ x 72″ capacity

- Maximum temperature of 1200° F

- Temperature uniformity +/- 5° F

Artificial Aging Heat Treatment Furnace

- NADCAP/IAI/Bombardier/Lockheed Martin Approved

- 64″ x 40″ x 64″ capacity

- Temperature range 500° F

- Type J thermocouples

- Electronic data logger

- Networked

Non-Destructive Testing (NDT)

Cyclone’s Heat Treating is approved to NADCAP specifications and features drop-bottom and artificial aging furnaces designed to heat-treat and age both rough and machined aluminum parts. Automated to maximize efficiency, these machines ensure quality without long lead times.

Shot Peening

Shot peening realigns molecules in ferrous, non-ferrous and exotic alloys, guarding the metal against stress-corrosion and cracking. The net result? Lighter, stronger parts meaning safer aircraft with longer life cycles.

Cyclone performs saturation shot peening, shot peen straightening, rotor flap peening and shot peen forming. Unlike its competitors, all of Cyclone’s peening equipment use stainless steel shot. The result is considerable waste reduction.

Anodizing

Facility #3 is home to Cyclone’s anodizing plant. Anodizing improves corrosion-resistance and prolongs the life of metal components. Built to NADCAP specifications, eight-tub system can manage parts up to 3 ft x 9 ft x 25 ft.

- Boric Sulfuric Acid Anodizing (BSAA)

- Chromic Acid Anodizing (CAA)

- Tartaric-Sulfuric Acid Anodizing (TSAA)

- Chem Film/Conversion Coating

Passivation

Primer and Topcoat

Cyclone provides a host of painting services including the application of primers, integrated fuel tank coating, and spraying epoxy and enamel top-coats. Our NADCAP compliant facility comes equipped with a drive-foam loop and an ASTM certified humidity-controlled cure oven which can accommodate parts up to 6 ft x 8 ft x 25 ft.

MinimumHeat TreatLot Chargesrange from $300-$650. Please see here.

For more information on our surface treatment and enhancement services, please contact us at info@cyclonemfg.com, or for quotes please

contact us at RFQ@cyclonemfg.com

Cyclone Manufacturing is dedicated to meeting environmental commitments as required by the municipality, province and federal government. As a demonstration of this commitment, we have attached the 2017 “Toxics Reductions Act – Summary” for nitric acid and hexavalent chromium and its compunds for review by the general public. Any questions regarding the document can be forwarded to info@cyclonemfg.com