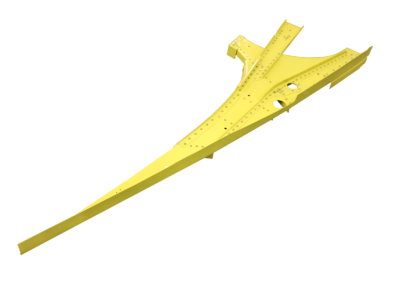

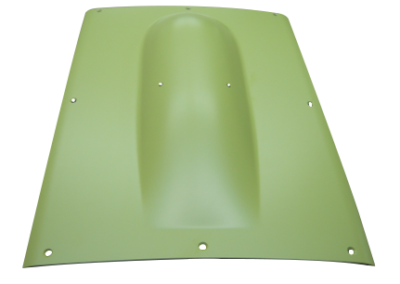

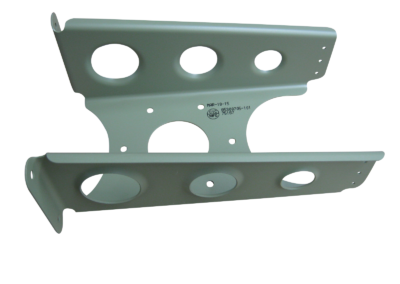

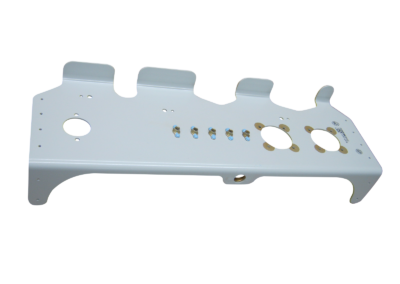

SHEET METAL FABRICATION

CNC Routers

144”x48”

Vacuum bed

Up to 1” thk

CNC Brake Press

Up to 130” long

20” axis Depth

125 Ton

4 axis

Rubber Press

24”x48”

3.5” Tool Height

2000 Ton

Cyclone expanded its sheet-metal fabrication, assembly and heat treatment capabilities with the addition of a second, state-of-the art 40,000 square foot facility in Milton, Ontario. The facility is located 15 km west of the main office.

The facility utilizes brake and rubber press technologies as well as multiple CNC routers and automated deburring machines.

Automated Deburring

48” x Infinite Length

Aluminum Oxide Brushes

Vacuum Belt

Extrusion Stretch Forming

120” x Length

5 Ton Capability

Having all of this equipment under one roof enables Cyclone to deliver comprehensive and cost-effective sheet metal fabrication services, all in one place. In addition to cutting and forming, Cyclone also provides on-site heat treatment, aging, freezing, sub-zero storage, and corrective forming.

The advantage to customers is noticeable: reduced costs, improved accountability and short production lead-times.