Quality

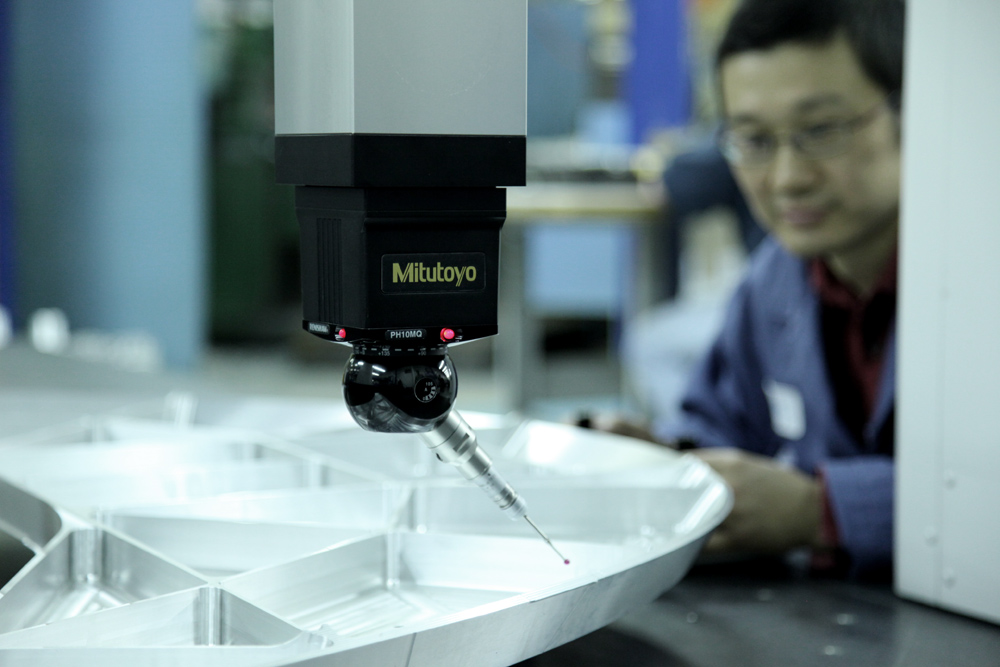

Cyclone’s AS9100D certified quality system is utilized to ensure customer requirements are monitored and satisfied on a continual basis. This is achieved through communication with the quality management team as well as support from a highly experienced inspection department. A wide array of inspection equipment is available to monitor and verify the numerous processes taking place throughout Cyclone’s various facilities. This includes a world class layout floor for First Article Inspections (FAIs), an in-house chemical processing laboratory and a metrology department able to provide internal calibrations for an array of tools.

Cyclone’s internal quality department ensures that parts are manufactured to OEM specifications. CMM reports indicate precise dimensions and confirm that parts conform to customer requirements.